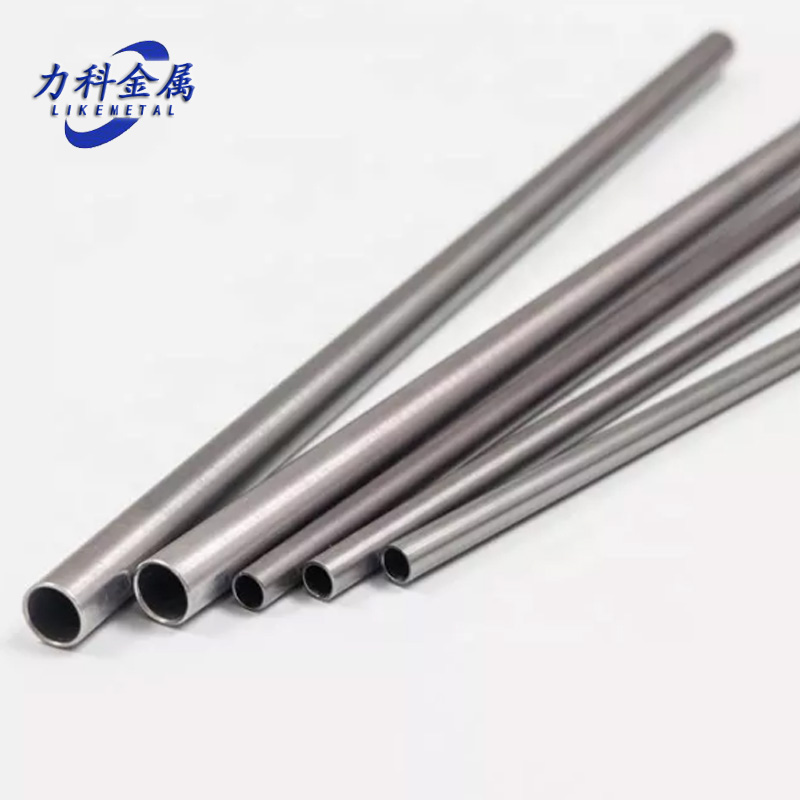

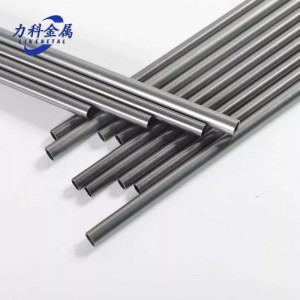

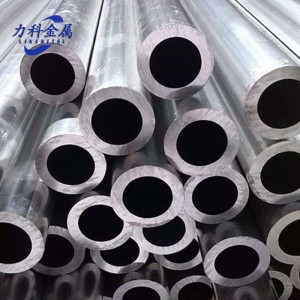

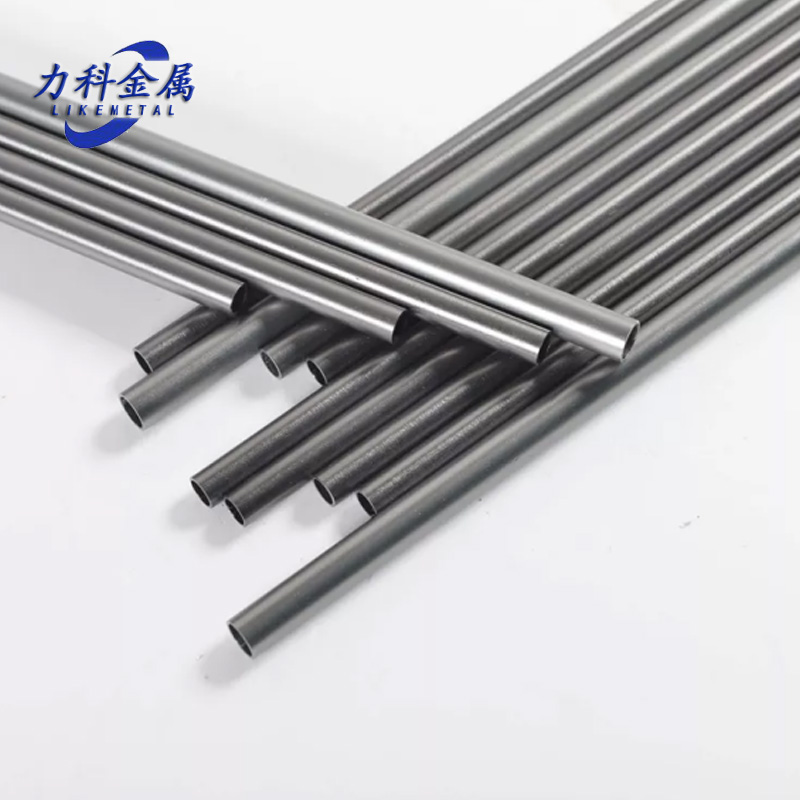

Polished Aluminum Half Round Pipe

|

Mechanical Property |

||||||||

|

ALUMINUM |

Grade |

Normal |

Temper |

Tensile Strength |

Yield Strength |

Elongation% |

Brinell Hardness |

|

|

Plate |

Bar |

|||||||

|

1XXX |

1050 |

O,H112,H |

O |

78 |

34 |

40 |

- |

20 |

|

1060 |

O,H112,H |

O |

70 |

30 |

43 |

- |

19 |

|

|

Al-Cu |

2019 |

O,T3,T4,T6,T8 |

T851 |

450 |

350 |

10 |

- |

- |

|

2024 |

O,T4 |

T4 |

470 |

325 |

20 |

17 |

120 |

|

|

Al-Mn |

3003 |

O,H112,H |

O |

110 |

40 |

30 |

37 |

28 |

|

3004 |

O,H112,H |

O |

180 |

70 |

20 |

22 |

45 |

|

|

Al-Si (4XXX) |

4032 |

O,T6,T62 |

T6 |

380 |

315 |

- |

9 |

120 |

|

Al-Mg |

5052 |

O,H112,H |

H34 |

260 |

215 |

10 |

12 |

68 |

|

5083 |

O,H112,H |

O |

290 |

145 |

- |

20 |

- |

|

|

Al-Mg-Si |

6061 |

O,T4,T6,T8 |

T6 |

310 |

275 |

12 |

15 |

95 |

|

6063 |

O,T1,T5,T6,T8 |

T5 |

185 |

145 |

12 |

- |

60 |

|

|

Al-Zn-Mg |

7003 |

T5 |

T5 |

315 |

255 |

15 |

- |

85 |

|

7075 |

O,T6 |

T6 |

570 |

505 |

11 |

9 |

150 |

|

Standard: GB, JIS, ASTM, DIN, EN, AISI

Place of Origin: Shandong, China

Brand: LIKE

| Thickness | 1.8 - 20 mm |

| Length: | 12M, 6m, 6.4M |

| Outer Diameter: | 19 - 660 mm |

Tolerance: ±0.1mm

Delivery time: 7-15 days

Surface finishing: 2B, 2D, No. 1, No. 4, BA, HL, 6K, 8K, polishing, annealing, pickling, bright, etc.

Certificate: ISO9001

Supply capacity: 20,000 tons/year

MOQ: 1 ton

Payment: 30%TT+70%TT/LC

Payment: T/T, L/C, Western Union

Tests: squash test, extension test, hydrostatic test, crystal decay test, heat resistance

Alumin(i)um Tube/Alumin(i)um Pipe Production Process:

The alloy aluminum tube profile is mainly produced by the extrusion method, while the wire rod is produced by the stretching method. The most commonly used extrusion processes are forward extrusion and reverse extrusion. Extruded alloy aluminum pipes and profiles adopt the production process of ingot heating-extrusion-finishing; for heat-treated aluminum alloys that can be strengthened, quenching and aging treatment are also required. The aluminum alloy wire adopts the production process of hot extrusion-annealing-stretching-heat treatment-finishing. The aluminum wire for the conductor is mainly produced in the wire factory, and generally adopts the production process of first continuous casting and rolling to produce aluminum wire rod and then stretching.

● Our Company Technology;

With a Good Team, It is a Leading Steel Stockist, Distributor and Exporter Firm and Also Do the Slitting and Cuttings;

● Our Major Stainless Steel Products:

Stainless Steel Sheets, Stainless Steel Pipes, Stainless Steel Bars and Carbon Steel Bars,stainless Steel Wires,stainless Steel Coils, Stainless Steel Strips.ect.

● As the First-class Suppliers and Competitive Prices;

Established Good Relationships from Kuwait, Russia, Ukraine, Lithuania, Greece, Belarus, Romanian, Belgium, Brazil, Argentina, Mexico, Tunis, Kenya, Etc.

Q: How Do You Control the Quality?

A: We Have Professional Inspectors to Analyze Chemical Composition of Raw Materials and Test the Finished Products Strictly According

Q: Can You Accept the Customization?

A: Yes. if You Have Special Requirements on Products or Packages, We Can Do Customization for You.

Q: Can You Accept Trial Orders?

A: If You Want to Place a Trail Order As the Beginning of Our Cooperation, We Can Accept Smaller Quantity at Frist.surely We Will Have Further and Longer Partnership After the Beginning.

Q: How to Get a Sample?

A: Free Samples Are Available for Your Checking and Test.

Q: How to control and guarantee your shipment quality?

A: 1) All our factories are ISO9001 certified facility; 2) World famous origin mills as TISCO, Baosteel;

3) Ex factory inspection by our own laboratory; 4) SGS/BV Third party inspection before delivery;